The Challenge

“EMS personnel experience injuries at a higher rate than workers in many other occupations…Beyond the effects faced by the injured worker themselves, the workforce can suffer from decreased productivity, inadequate staffing levels and other increased costs.”

Source: Reichard, A. A., Wijetunge, G. U., Marsh, S. M., & Konda, S. (2017, November 06). 5 causes of high injury rate in EMS providers. Retrieved September 24, 2020.

The Result

An affordable stretcher fastening system that leverages simple mechanics to relieve EMTs’ fear and risk of injury and keep patients safer in the process.

ProXtend

How might we improve the work environment of EMTs so they can save lives more effectively?

Research, Innovation | Summer 2019

Interviews

During an initial visit to the Norwood EMS & Fire Department, four experienced EMT/Firefighters immediately named the manual stretcher as the most frustrating tool they use. They wanted a power cot, but the department couldn’t afford the upgrade. Digging further revealed their universal fear of hurting themselves in the process of saving lives.

Sierra, a new EMT in Upstate New York, reported the same fear and wishes that her home EMS department, TLC EMS, had automatic stretchers like the one she uses at her school with RIT Ambulance.

KEY INSIGHT

EMTs fear injury on the job and sometimes jeopardize their own safety in the process of saving a life.

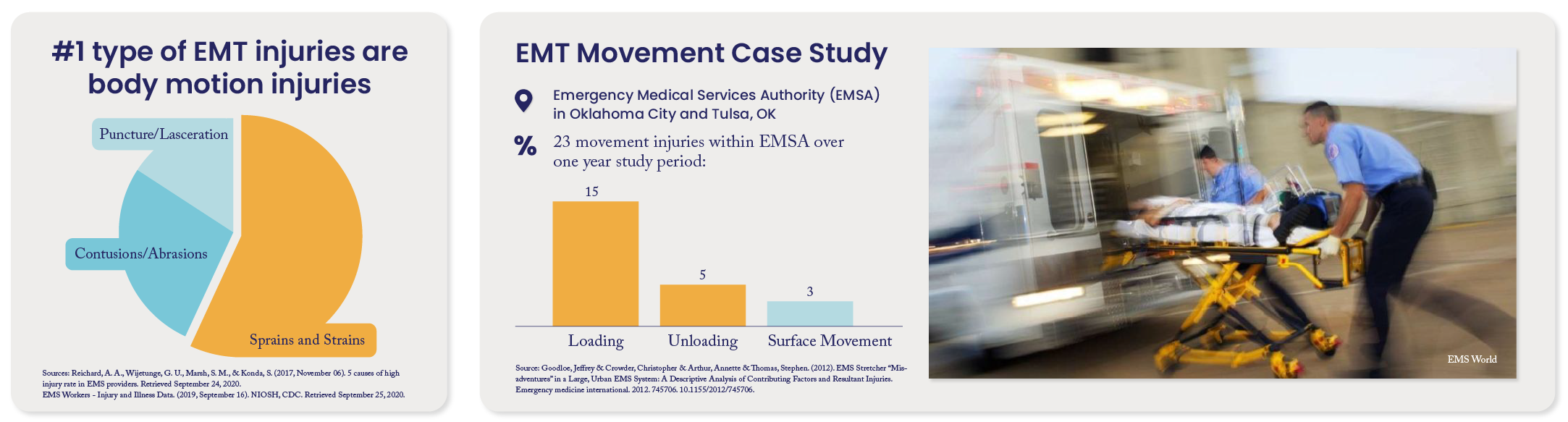

When are EMTs most at risk of injury on the job?

In depth secondary research revealed that EMTs face a variety of injuries, but most common are the muscular injuries that result from lifting and moving heavy loads. Once again, manual stretchers rose to the forefront as a high risk since they are the heaviest piece of EMT equipment, made even heavier when loaded with a patient (who are getting even heavier with the rise of obesity).

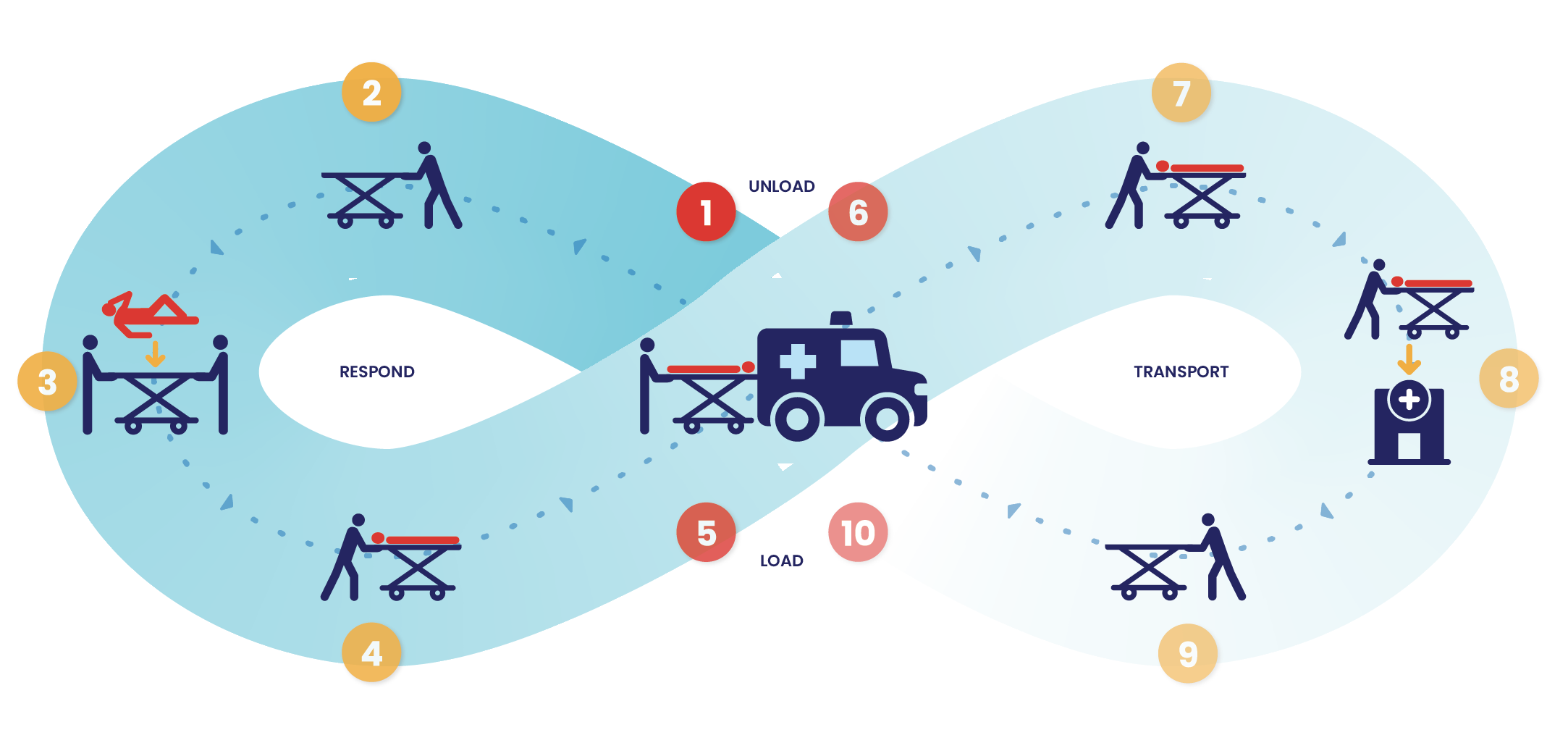

EMT-Stretcher Journey Map

An analysis of EMT-stretcher interactions demonstrated the central role of loading and unloading the ambulance. Of the ten interaction, six involve dangerous lifting (see 1, 3, 5, 6, 8, 10). Four of those six dangerous interactions, or 66%, involve loading and unloading the ambulance. Therefore, developing a solution to reduce or eliminate risk during stretcher loading/unloading will have the greatest impact on EMT-stretcher safety.

KEY INSIGHT

Loading & unloading the ambulance is a central and recurring step.

Task Analysis | Loading & Unloading

Blind Alignment

In order to secure the stretcher, the EMT must align a nob with a narrow track on the floor of the ambulance. The trick? This all happens underneath the stretcher.

Awkward Lift

Once the EMT fumbles through the blind alignment, they have to lift their end of the stretcher. Due to the ambulance loading height, this requires them to support the load with a shrug of their shoulders.

Risk of Collapse

Next, a secondary EMT must bend over to manually life the stretcher legs. This is a major moment of fear, because if the main EMT were to lose their grip (or worse) the entire load comes crashing to the ground.

Cumbersome Locking

Finally, once the stretcher is all the way in the ambulance, the main operator must jerk the load to one side in order to engage the transport lock. This is uncomfortable for both the patient and EMT.

Problems with the Current Solution

The current antidote to the lifting risks faced by EMTs come in a variety of powered stretcher and fastening systems. However, some systems still require EMTs to bear significant weight. Furthermore, automatic stretchers are even heavier than manual stretchers, introducing an even bigger risk should the technology fail. Finally, a fully powered stretcher system costs upwards of $40,000, well beyond reach for many EMS departments.

OBJECTIVE

Develop a low-cost, retrofit tool to assist loading and unloading.

Mechanism Explorations

Inspired by common simple mechanisms — from pulley systems to car jacks, wheels to ratchets — I explored methods of transferring weight and lightening loads.

Prototyping

Drawer Glide Inspiration

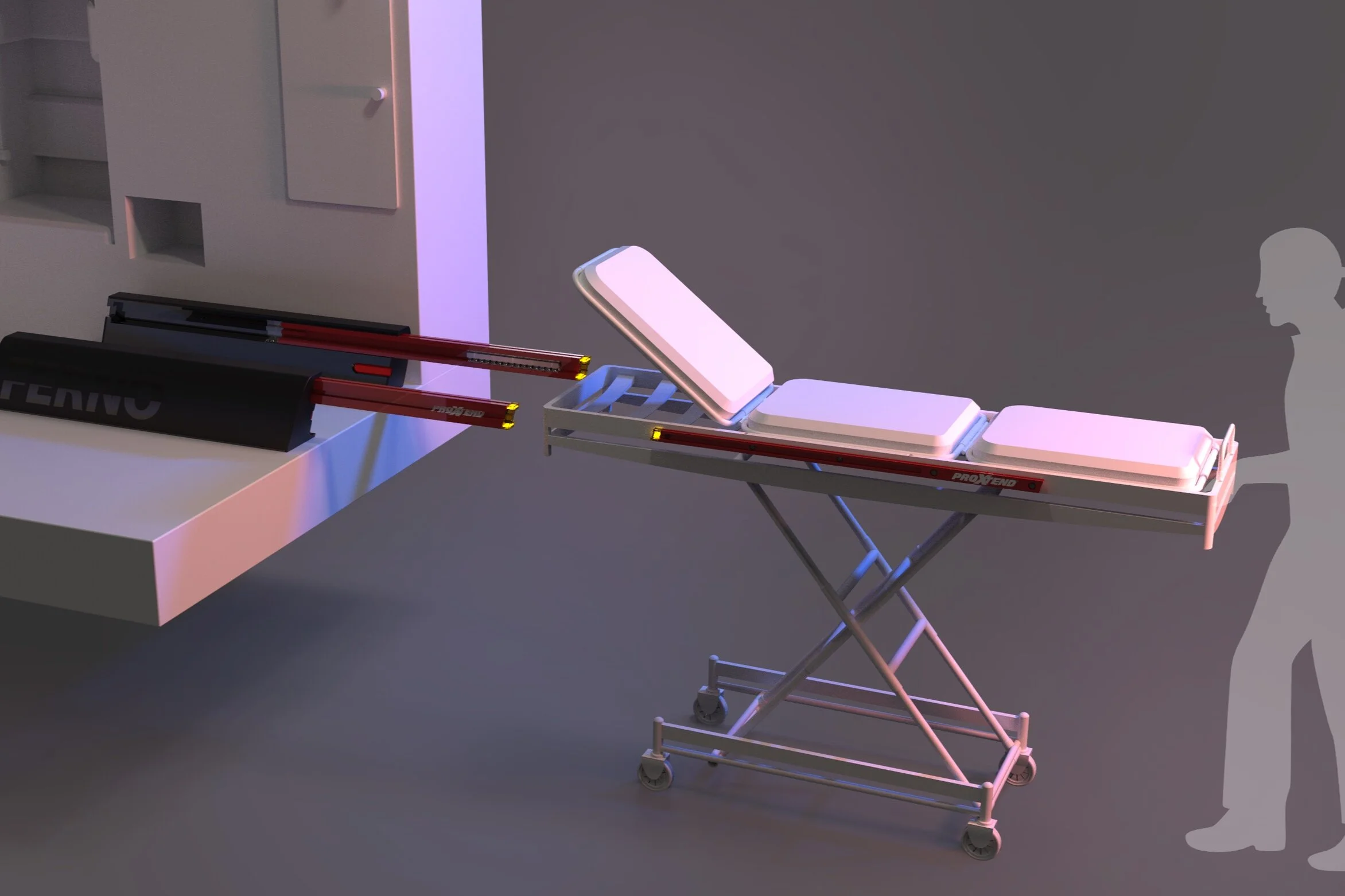

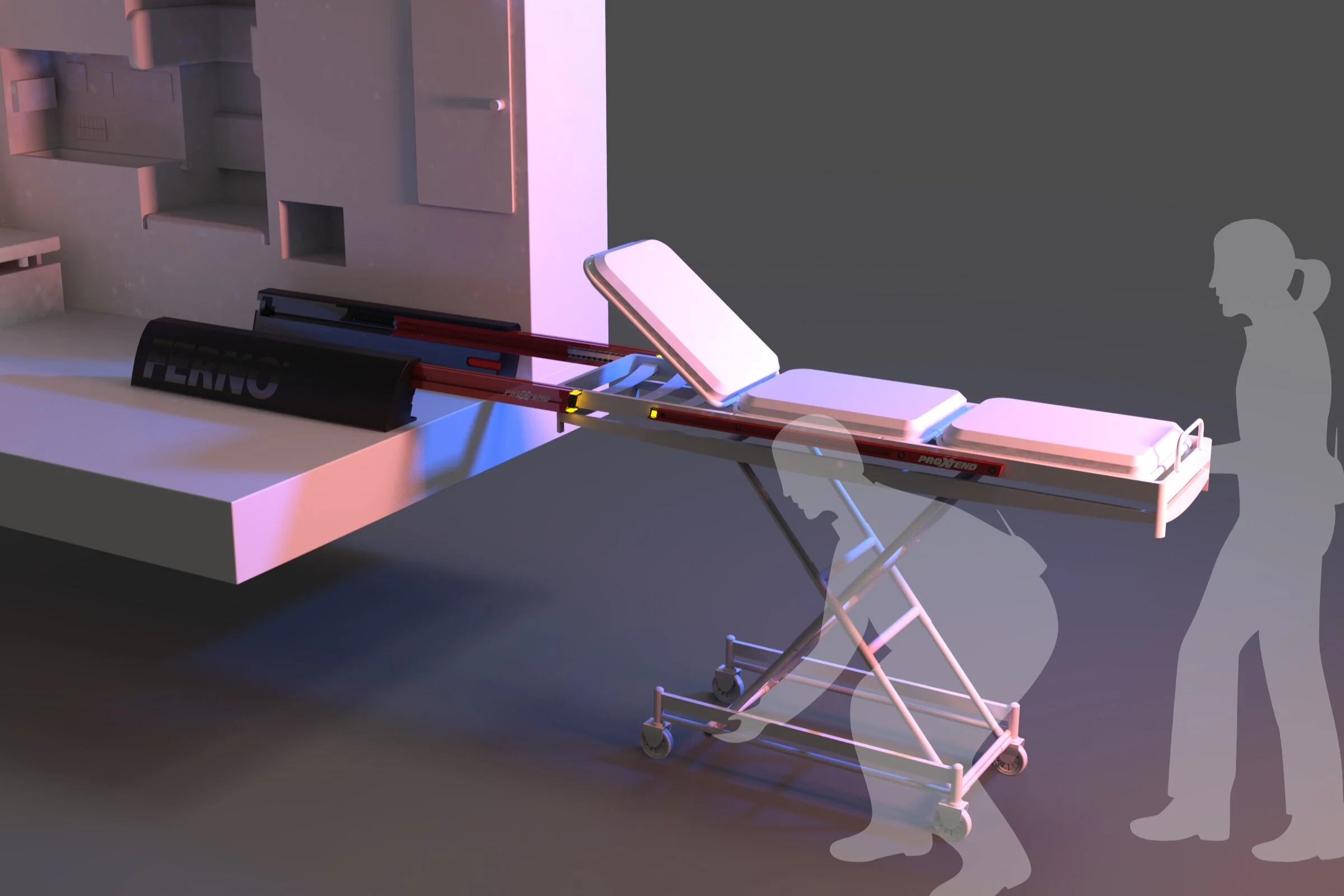

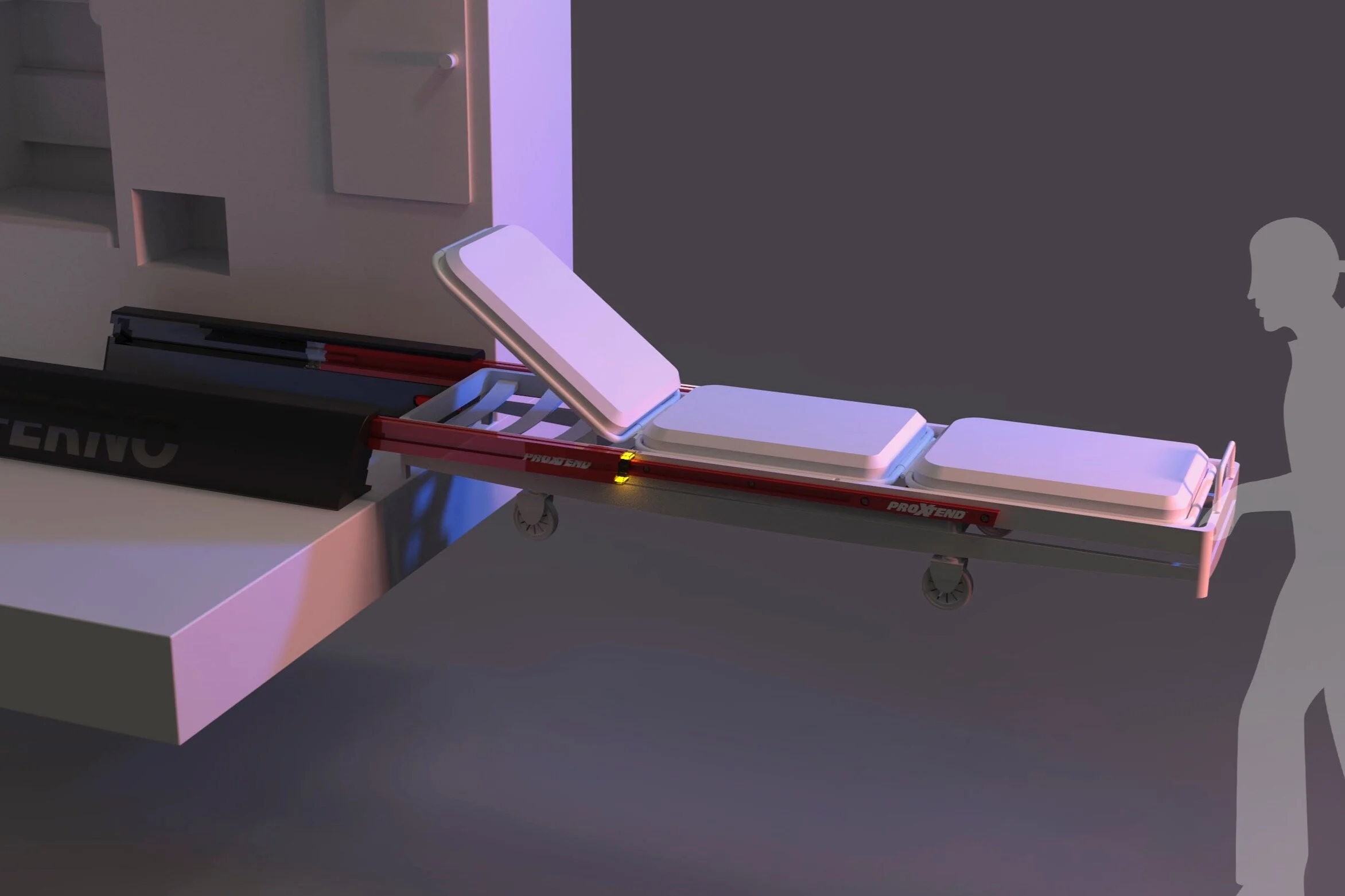

The winning mechanism was a heavy duty drawer glide, as the motion of inserting and removing a drawer parallels loading and unloading a stretcher. Furthermore, I identified opportunities to build in more speed and efficiency into this new load/unload process, such as highly visible alignment and integrated transit locks.

Final Concept

Illuminated Alignment

With the ProXtend, the alignment mechanisms are now in place visible to all operators. Integrated LED accents illuminate alignment for improved visibility, no matter the setting or time of day.

Never Collapse

The moment the stretcher glide meets the extended ones, the patient load is transferred to the ambulance, so the secondary operator can lift the legs without worrying about collapse or other mishaps.

No More Lift

Since the weight has already been transferred to the ambulance, the main operator bears no load during the rest of the process. They just have to push the stretcher into place.

Integrated Locking

Instead of jerking the stretcher to the side to engage the transport lock, with the ProXtend an EMT simply pushes the stretcher all the way into place and the locks engage automatically.